|

|

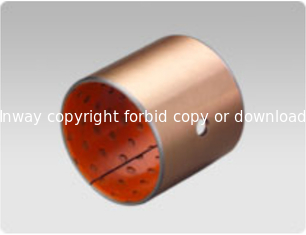

INW-2S Composite Bushings , Steel Backing Self Lubricating Dry Bush

|

Product Details:

Payment & Shipping Terms:

|

| Application: | Engine Bearing | Size: | Standard |

|---|---|---|---|

| Standard: | DIN 1494 | Material: | Steel+Bronze +PTFE |

| Type: | With Split | Technical: | Dry Bushing |

| High Light: | composite bearing,compound bearings |

||

INW-2S Composite Bushings , Steel Backing Self Lubricating Dry Bush

Features:

INW–2S Suitable for dry running, low coefficient of friction, lower wear, good sliding characteristics, the transfer film created can protect the mating metal surfaces, suitable for rotating and oscillating movement, high chemical resistance, low absorption of water and swelling. The CSB-40 improved the friction and much good wear resistance over the common CSB-50 range under lubricated operation.

| Max. load | Static | 250N/mm2 | Max.speed | Dry running | 0.08~0.20 | |

| Very low speed | 140N/mm2 | Hydrodynamicoperation | 0.02~0.08 | |||

| Rotatingoscillating | 60N/mm2 | Frictioncoefficient | Dry | 2m/s | ||

| Hydrodynamic | >2m/s | |||||

| Max. PVdryrunning) | Short-termoperation | 3.6N/mm2*m/3 | Thermal conductivity | 42W(m*K)-1 | ||

| Continuousoperation | 1.8N/mm2*m/3 | |||||

| PV max. hydrodynamic | -195℃~+280℃ | Coefficient of thermalexpansion | 11*10-6*K-1 | |||

Structure:

1. PTFE/Fibre mixture thickness 0.01~0.03mm. It is thecontact surface for the rotating shaft. Minute partides of the PTFE layer and the sintered bronze material combine to create a solid lubricant film, which coats the shaft.

2. Sintered bronze powder thickness 0.20*0.35mm,A special composition of powdered copper is thermally fused to the steel backing. This contact layer acts as an anchor for the PTFE layer and conducts the thermal build up away from the bearing surfaces.

3. Low-carbon steel backing. Setting the foundation of the bushings, the steel back provides exceptional stability, load carrying and heat dissipation characteristics.

Typical Applications:

1. This material meets the demanding criteria for long life and maintenance free performance with or without lubrication.

Automotive: tractors, combines, crop sprayers, earth-movers, graders and other construction, auto machines, specific uses in power steering cylinders, steering gear thrust washers, disc brakes, calipers and pistons, shock absorbers, governor linkage, windshield wiper motor, tilt gear assemblies...

2. Business machines: photocopy machines, typewriters, mail sorters, postage meter systems, computer terminalprinters and peripheral equipment,automaticprinting devices, mail processing machinery...

Hydraulics and valves: pumps including gear, rotary, water, axial piston, and other types, ball, butterfly, poppet steam, and other valves and valve trunnions...

3. Home appliances: tape recorders, refrigerators, air conditioners, cleaners, polishers, sewing machines, ovens, dishwashers, clothes washing machines...And materials handling, marine engine, packaging, textile equipment, tools...etc.

| d | d | axle | housing h7 | wall thickness | h oil hole | f 1 | f 2 | l 0 -0.40 | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| min | max | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | 60 | |||||||

| 10 | 12 | 10 -0.022 | 12 +0.018 | 0.955 | 0.980 | 4 | 0.6 | 0.3 | 1010 | 1015 | 1020 | |||||||

| 12 | 14 | 12 -0.027 | 14 +0.018 | 1210 | 1215 | 1220 | ||||||||||||

| 14 | 16 | 14 -0.027 | 16 +0.018 | 1415 | 1420 | |||||||||||||

| 15 | 17 | 15 -0.027 | 17 +0.018 | 1515 | 1520 | 1525 | ||||||||||||

| 16 | 18 | 16 -0.027 | 18 +0.018 | 1615 | 1620 | 1625 | ||||||||||||

| 18 | 20 | 18 -0.027 | 20 +0.021 | 1815 | 1820 | 1825 | ||||||||||||

| 20 | 23 | 20 -0.033 | 23 +0.021 | 1.445 | 1.475 | 0.6 | 0.4 | 2015 | 2020 | 2025 | 2030 | |||||||

| 22 | 25 | 22 -0.033 | 25 +0.021 | 2215 | 2225 | |||||||||||||

| 25 | 28 | 25 -0.033 | 28 +0.021 | 6 | 2515 | 2520 | 2525 | 2530 | ||||||||||

| 28 | 32 | 28 -0.033 | 32 +0.025 | 1.935 | 1.970 | 1.2 | 0.4 | 2820 | 2830 | |||||||||

| 30 | 34 | 30 -0.033 | 34 +0.025 | 3020 | 3025 | 3030 | 3035 | 3040 | ||||||||||

| 35 | 39 | 35 -0.039 | 39 +0.025 | 3520 | 3530 | 3535 | 3540 | |||||||||||

| 40 | 44 | 40 -0.039 | 44 +0.025 | 8 | 4020 | 4030 | 4035 | 4040 | 4050 | |||||||||

| 45 | 50 | 45 -0.039 | 50 +0.025 | 2.415 | 2.460 | 1.8 | 0.6 | 4520 | 4530 | 4540 | 4545 | 4550 | ||||||

| 50 | 55 | 50 -0.039 | 55 +0.030 | 5030 | 5040 | 5050 | 5060 | |||||||||||

| 55 | 60 | 55 -0.046 | 60 +0.030 | 5530 | 5540 | 5550 | 5560 | |||||||||||

| 60 | 65 | 60 -0.046 | 65 +0.030 | 6030 | 6040 | 6050 | 6060 | |||||||||||

| d | d | axle | housing h7 | wall thickness | hoil hole | f 1 | f 2 | l 0 -0.40 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| min | max | 40 | 50 | 60 | 80 | 90 | 95 | 100 | 110 | 120 | |||||||

| 65 | 70 | 65 -0.046 | 70 +0.030 | 2.415 | 2.460 | 8 | 1.8 | 0.6 | 6540 | 6560 | |||||||

| 70 | 75 | 70 -0.046 | 75 +0.030 | 7040 | 7050 | 7080 | |||||||||||

| 75 | 80 | 75 -0.046 | 80 +0.030 | 7540 | 7560 | 7580 | |||||||||||

| 80 | 85 | 80 -0.046 | 85 +0.035 | 2.385 | 2.450 | 9.5 | 1.8 | 1.8 | 8040 | 8060 | 8080 | ||||||

| 85 | 90 | 85 -0.054 | 90 +0.035 | 8540 | 8560 | 8580 | |||||||||||

| 90 | 95 | 90 -0.054 | 95 +0.035 | 9040 | 9060 | 9080 | 9090 | ||||||||||

| 100 | 105 | 100 -0.054 | 105 +0.035 | 10050 | 10080 | 10095 | |||||||||||

| 105 | 110 | 105 -0.054 | 110 +0.035 | 10560 | 10580 | 10595 | 105110 | ||||||||||

| 110 | 115 | 110 -0.054 | 115 +0.035 | 11060 | 11080 | 11095 | 110110 | ||||||||||

| 120 | 125 | 120 -0.054 | 125 +0.040 | 1.8 | 0.6 | 12060 | 12080 | 120110 | |||||||||

| 125 | 130 | 125 -0.063 | 130 +0.040 | 12560 | 125110 | ||||||||||||

| 130 | 135 | 130 -0.063 | 135 +0.040 | 13050 | 13060 | 13080 | 130100 | ||||||||||

| 140 | 145 | 140 -0.063 | 145 +0.040 | 14050 | 14060 | 14080 | 140100 | ||||||||||

| 150 | 155 | 150 -0.063 | 155 +0.040 | 15050 | 15060 | 15080 | 150100 | ||||||||||

| 160 | 165 | 160 -0.063 | 165 +0.040 | 9.5 | 16050 | 16060 | 16080 | 160100 | |||||||||

| 170 | 175 | 170 -0.063 | 175 +0.040 | 17050 | 17080 | 170100 | |||||||||||

| 180 | 185 | 180 -0.063 | 185 +0.046 | 18050 | 18060 | 18080 | 180100 | ||||||||||

| 190 | 195 | 190 -0.072 | 195 +0.046 | 19050 | 19060 | 19080 | 190100 | 190120 | |||||||||

| 200 | 205 | 200 -0.072 | 205 +0.046 | 20050 | 20060 | 20080 | 200100 | 200120 | |||||||||

| 220 | 225 | 220 -0.072 | 225 +0.046 | 9.5 | 22050 | 22060 | 22080 | 220100 | 220120 | ||||||||

| 240 | 245 | 240 -0.072 | 245 +0.046 | 24050 | 24060 | 24080 | 240100 | 240120 | |||||||||

| 250 | 255 | 250 -0.072 | 255 +0.052 | 25050 | 25060 | 25080 | 250100 | 250120 | |||||||||

| 260 | 265 | 260 -0.081 | 265 +0.052 | 26050 | 26060 | 26080 | 260100 | 260120 | |||||||||

| 280 | 285 | 280 -0.081 | 285 +0.052 | 28050 | 28060 | 28080 | 280100 | 280120 | |||||||||

| 300 | 305 | 300 -0.081 | 305 +0.052 | 30050 | 30060 | 30080 | 300100 | 300120 | |||||||||

Contact Person: james

Tel: +8618657357275

-

INW-2X Marginal Lubrication Bearing Steel Backing DIN 1494 Standard

-

SF-2 DX Composite Bushings POM Metal Polymer Plain Bearings Grease Lubricated

-

Metal Polymer Anti Friction Plain Bearings Sintered on Steel and PTFE Pb.SF-1 DU DP10

-

INW-20 Dry Bushing With Tin Outside SF-2 DX Steel Bronze Powder POM / Fibre

-

High Strength Composite Bushings INW-CR EPG EPX INW-CR Series Material

-

INW-EPB Plastic Compound Bearings Crystal Engineering Plastic Yellow Color